01-30

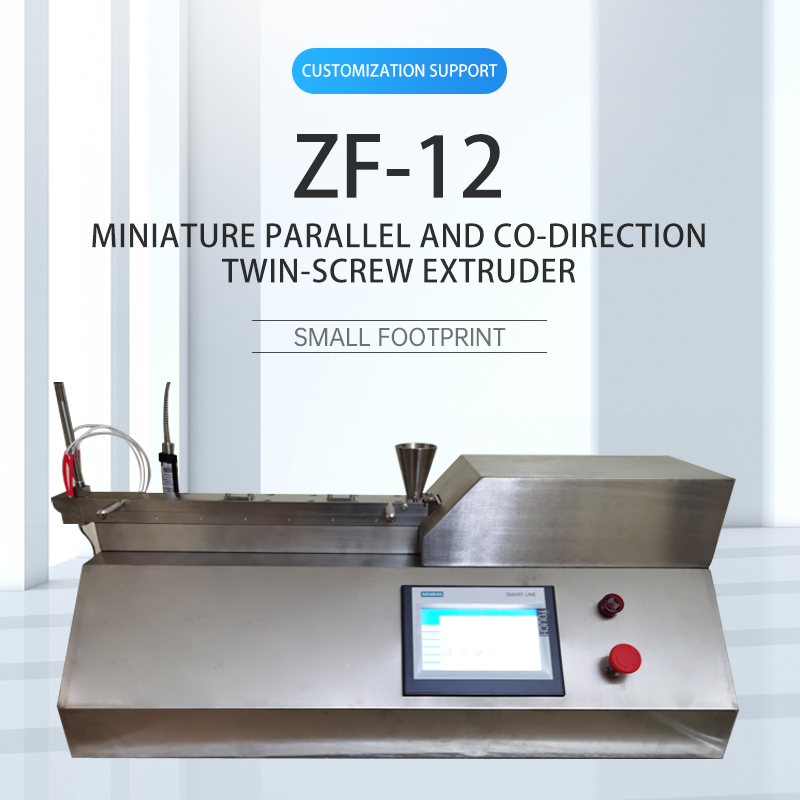

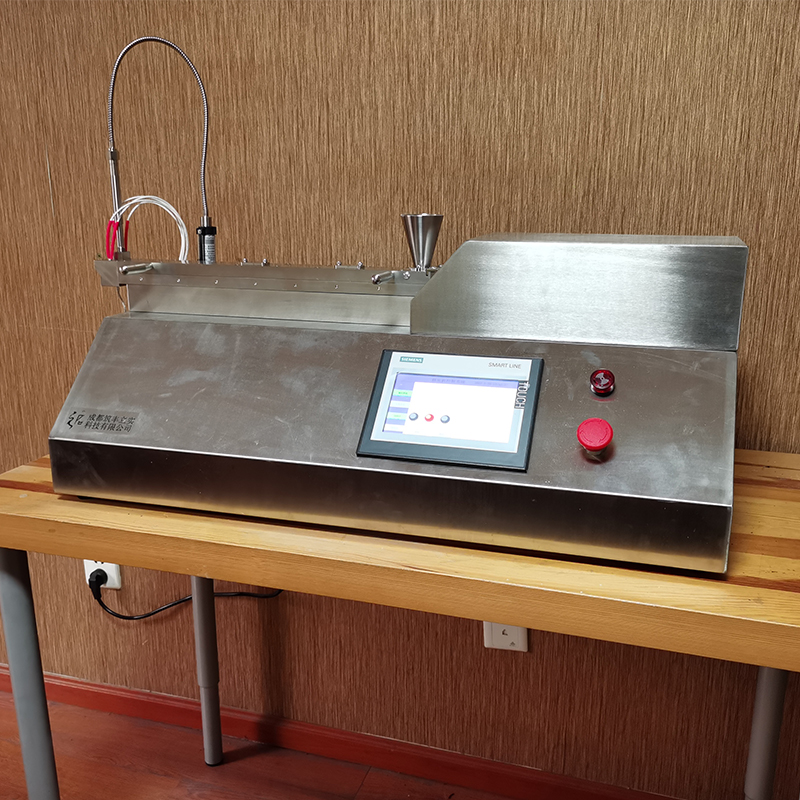

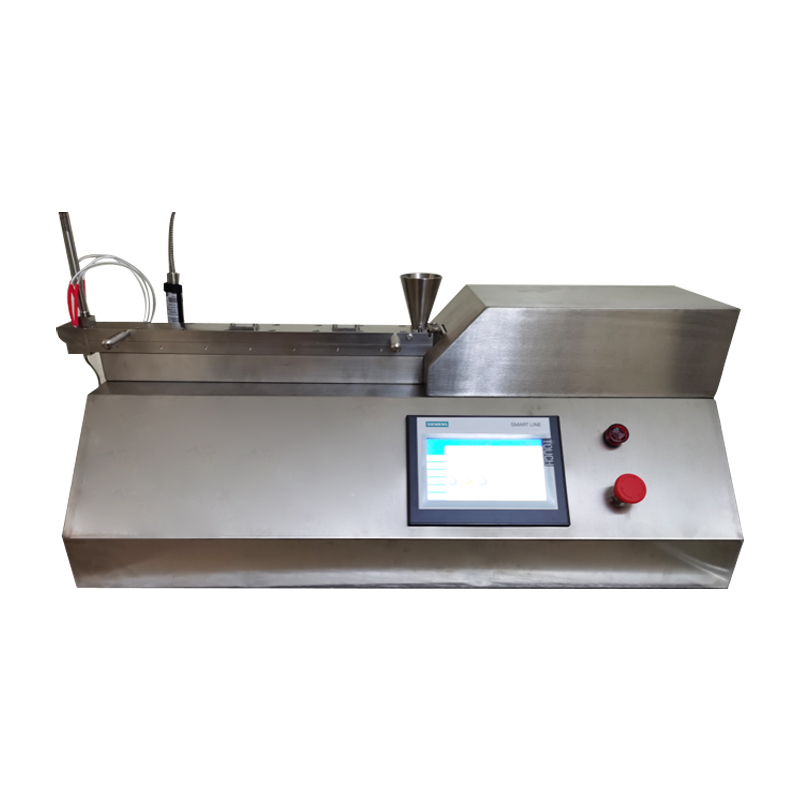

MINIATURE PARALLEL AND CO-ROTATING TWIN-SCREW EXTRUDER ZF-12

2023-03-16

2023-03-16

The twin-screw hot melt extruder ZF-12 is the best of the current domestic miniature twin-screw extruders, which can achieve both high material efficiency and manual efficiency by.

1. Short average material retention time and narrow range of residence time distribution.

2. With a minimum feed of only 30g, only a small amount of active pharmaceutical ingredients is required to generate well-dispersed and uniformly distributed products, greatly reducing development costs.

3. Fully scalable to stand-alone polymer modification/pharmaceutical mixing systems and continuous production lines, with simultaneous access to process formulations and related experimental data. Small-scale production is also possible, bringing great convenience to research and production.

4. Complete micro-compounding extrusion solutions are available with a wide range of accessories for 12mm twin-screw extruders.

ZF-12 parallel twin-screw extruder is mainly used for.

1. Polymer material co-blending modification experiment.

2. Drug hot melt extrusion preparation development.

3. Solid dispersion preparation.

Especially in pharmaceutical field, HME has obvious advantages compared with traditional drug formulation technology. It is a solvent-free technology, belongs to a continuous operation (requiring fewer processing steps), does not require major downstream processing such as drying, compression, granulation, etc., and improves bioavailability due to the final dosage form of the drug as a molecular dispersion, while slow and controlled release models of the drug can be easily achieved.

The applications mainly include solubilization of insoluble drugs, drug taste masking and moisture control, preparation of slow and controlled release drug delivery systems, 3D printing, etc.

Chengdu Zhufeng Lisi Technology Co., Ltd. was founded on May 15, 2019 and is located at 888 South Tianfu Avenue, Huayang Street, Tianfu New District, Chengdu, Sichuan Province. The main business is: micro co-mingled extrusion sets of equipment and drug hot melt extrusion process equipment development and manufacturing. At present, we have designed and developed a series of miniature desktop twin-screw extruders ZF11--ZF12 independently and successfully launched. We provide experimental platform for domestic enterprises, universities and research institutes, and reduce the feasibility verification and equipment procurement cost. We also conduct process research on drug and polymer compounding based on existing equipment. About equipment opportunities: imported equipment is expensive, equipment localization demand is clear; equipment advantages: industry has a benchmark product in the short term to take the follow strategy, play the latecomer advantage; domestic just started existing manufacturers without core technology (core components materials and pinion box). The company has a professional technical research and development team composed of highly educated personnel, and has applied for a number of exclusive technologies. We always adhere to the core values of "scientific and technological innovation, cooperation and win-win", timely solve all kinds of difficult problems of customers, so that customers can rest assured that no worries. Here, we warmly welcome people from all walks of life to visit our company and discuss cooperation! Welcome customers to call and consult!

Wang Xiaofei

womenhenqiang2009@163.com